8D Problem Solving Model - Auto NCR

Posted on 2021-11-20

It is normal for organizations to stumble into challenges as they grow. The challenge starts with on how we can correctly identify the problem and finding the effective solutions are not that easy as well.

Trying out several techniques that will guide each organization for finding better and effective solutions is one way to get the best results as possible. Nowadays, there are already established tools that will enable you for a better problem-solver.

- Creative thinking

- Rational thinking

- Decision thinking

- Risk analysis

- Check-sheets and Work Instructions

- Pareto Diagrams and Trend Charts

- Process Flow Diagrams, FMEA, and Control Plans

- Cause and Effect Diagrams

- Dot Plots and Histograms

- Scatter Plots and Analysis of Variation

- Control Charts

- Advanced Statistical and Data Analysis Tools

-

- Simulation

- Regression Analysis

- Designed Experiments

-

The above-mentioned tools are just some, but when used in a solid procedure or technique, problem solving makes it even more effective. One technique or procedure that I am going to introduce to you is by using the “8 Disciplines of Problem Solving.”

Now let’s begin on knowing what this technique is all about.

History

Eight disciplines problem solving(8Ds) is a method developed at Ford Motor Company used to approach and to resolve problems, typically employed by engineers or other professionals. Focused on product and process improvement, its purpose is to identify, correct, and eliminate recurring problems. It establishes a permanent corrective action based on statistical analysis of the problem and on the origin of the problem by determining the root causes.

Source: https://en.wikipedia.org/wiki/Eight_disciplines_problem_solving

Usage

8D process addresses as follows.

- Customer complaints on the product

- Internal defects, failure, and scrap are present

- Regulation or safety issues has been discovered

Benefits

- Improved group arranged problem solving abilities

- Expanded knowledge of a structure for problem solving

- Better comprehension of how to utilize essential measurable devices needed for problem solving

- Improved viability and proficiency at problem solving

- A functional comprehension of Root Cause Analysis (RCA)

- Problem Solving exertion might be embraced into the cycles and strategies for the association

- Improved abilities for actualizing remedial activity

- Better capacity to recognize fundamental systemic changes and ensuing contributions for change

- More authentic and open correspondence in problem solving conversation, increasing effectiveness

- An improvement in administration's comprehension of issues and issue goal

More about Eight Disciplines (8D)

The eight disciplines (8D) model is a problem-solving approach typically employed by quality engineers or other professionals, and is most commonly used by the automotive industry but has also been successfully applied in healthcare, retail, finance, government, and manufacturing. The purpose of the 8D methodology is to identify, correct, and eliminate recurring problems, making it useful in product and process improvement.

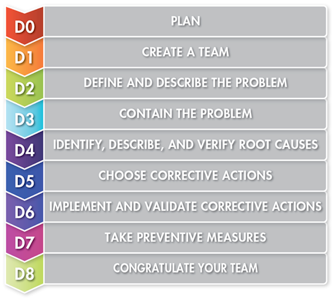

The 8D problem solving model establishes a permanent corrective action based on statistical analysis of the problem and focuses on the origin of the problem by determining its root causes. Although it originally comprised eight stages, or disciplines, the eight disciplines system was later augmented by an initial planning stage.

How to Use the 8D approach

D0: Plan - Plan for solving the problem and determine the prerequisites.

D1: Use a team - Select and establish a team of people with product/process knowledge.

D2: Define and describe the problem - Specify the problem by identifying in quantifiable terms the who, what, where, when, why, and how for the problem.

D3: Develop interim containment plan; implement and verify interim actions - Define and implement containment actions to isolate the problem from any customer.

D4: Determine, identify, and verify root causes and escape points - Identify all applicable causes that could explain why the problem occurred. Also identify why the problem was not noticed at the time it occurred. All causes shall be verified or proved, not determined by fuzzy brainstorming. One can use 5 Whys and cause and effect diagrams to map causes against the effect or problem identified.

D5: Choose and verify permanent corrections (PCs) for problem/nonconformity - Through preproduction programs, quantitatively confirm that the selected correction will resolve the problem for the customer.

D6: Implement and validate corrective actions - Define and implement the best corrective actions (CA).

D7: Take preventive measures - Modify the management systems, operation systems, practices, and procedures to prevent recurrence of this and all similar problems.

D8: Congratulate your team - Recognize the collective efforts of the team. The team needs to be formally thanked by the organization.

Source: https://asq.org/quality-resources/eight-disciplines-8d

NXPERT ONE -Auto NCR

NXPERT One Auto NCR, is a systematic way of managing your 8D Procedures of your entire orginization.Here are some features that will help you conduct this method in a very efficient way.

Investigate and report

NXPERT ONE assign new issues to both internal employees and external suppliers instantly.

NXPERT ONE guides the user through the 8D investigation workflow: Investigation request, containment, root cause analysis, and permanent solution deployment.

Full 8D investigation reports can be generated instantly by a single mouse click.

Visibility of status, ownership, and actions

Manual or paper-based issue investigation processes can be inefficient, slow, and difficult to measure. NXPERT ONE provides instant issue management for your customers and suppliers. Investigation status is instantly available for review to make tracking problem resolution easy.

NXPERT ONE also provides total visibility for and your improving teams. It capture issues, conduct investigations, implement changes and track status instantly. Users get to see who’s responsible and what's been done. It also provides you with a simple user interface helps track each investigation through to closure.

For more information, please visit our NXPERT page or you may log your inquiries on our inquiry page to contact our team.

Recent Blogs